With sustainability goals becoming non-negotiable and waste reduction targets getting tighter every year, health and safety professionals are discovering that PPE management has a much bigger environmental and financial impact than most organizations realize.

The Hidden Cost of PPE Waste

Most organizations are throwing away thousands of pounds worth of perfectly good PPE every year – items that could be relaundered, recycled, or simply returned for proper disposal. Most of it ends up in general waste streams where it’s completely invisible to sustainability reporting.

The companies we work with are genuinely shocked when they calculate their actual PPE waste costs. It’s wasteful, expensive, and completely at odds with any serious sustainability strategy.

iVendScale: Intelligent PPE and MRO Inventory Management with Built-in Sustainability

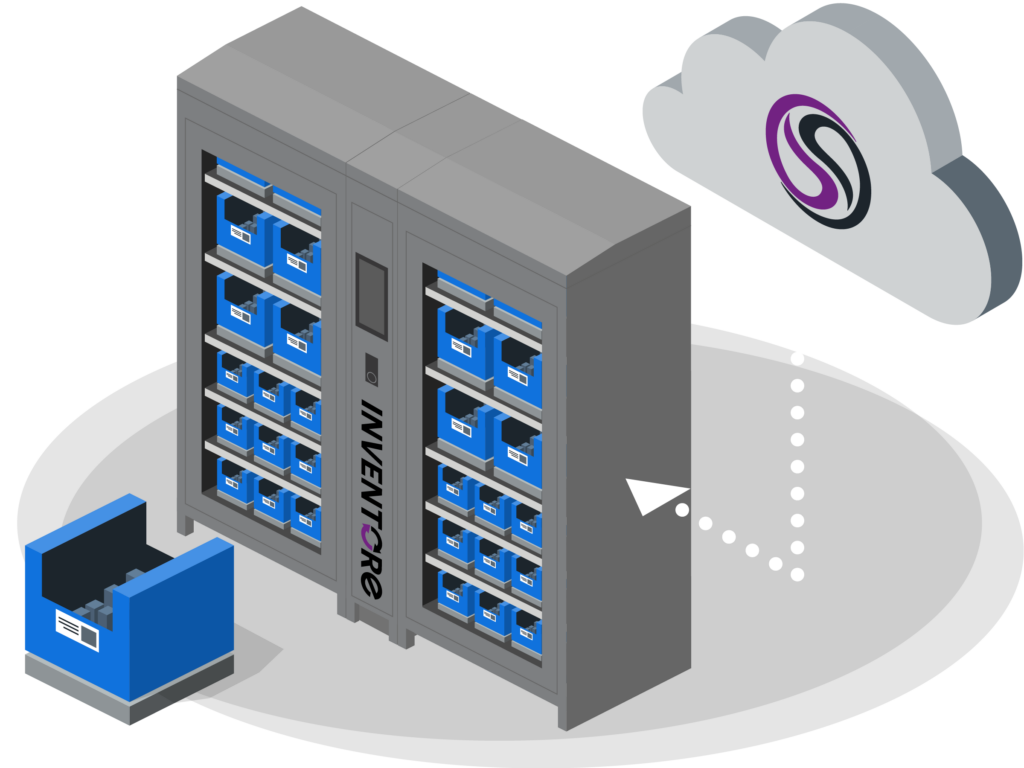

iVendScale from Inventor-e is a leading-edge, intelligent PPE and MRO vending solution that’s transforming how organizations manage their safety equipment while dramatically improving their environmental credentials.

Built-in Circular Economy

The game-changer is iVendScale’s “New for Old” system. Users can only access fresh PPE when they return used items to the designated cabinet. This creates an automatic collection point for relaundering, recycling, or proper disposal – no more items ending up in general waste. It’s circular economy thinking built right into your daily safety processes.

Dramatic Results

Organizations typically see 40% less PPE consumption, which translates directly into less waste, lower costs, and better sustainability metrics. The waste essentially becomes a thing of the past – everything gets captured for proper reuse or disposal, and your consumption drops dramatically.

Smarter Supply Chain

Optimized and automated stock management means fewer deliveries, reduced packaging, and a smaller carbon footprint from your PPE supply chain. When you’re not over-ordering and wasting stock, you’re not constantly calling for emergency deliveries either.

The Compliance Bonus

Here’s something that might surprise you – your compliance actually improves because the system ensures proper usage tracking and return protocols. You get better safety standards and better environmental performance at the same time.

Why This Matters Now

The companies that are getting ahead of this aren’t just looking at carbon emissions anymore – they’re tracking resource efficiency, circular economy metrics, and waste diversion rates. PPE is becoming a surprisingly big part of that conversation.

Whether you’re being pushed toward Net Zero targets, dealing with increasing waste disposal costs, or simply trying to get better visibility over your PPE spending, this feels like one of those solutions that actually makes financial and environmental sense at the same time.

The Reality Check

Most sites we visit have no idea what they’re really throwing away. Getting a handle on your actual PPE waste volumes might be worth doing anyway, regardless of what solution you choose. But if you’re serious about hitting your sustainability targets while maintaining top-tier safety standards, intelligent PPE inventory management like iVendScale might be exactly what you need.

The pressure is only going to increase from here, and the organizations that get ahead of this now will have a significant advantage when waste reduction becomes even more critical to their operations and reporting. Talk to us today about how smart PPE management can help you reduce waste and improve visibility.